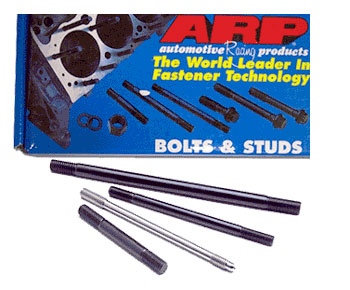

ARP Pro Series head studs are finest on the market today! ARP® uses a premium grade 8740 alloy that is rated far superior to "aircraft" quality. Each stud is then placed vertically in special racks and precisely heat-treated. This procedure ensures complete heat penetration and the results are far superior to those lesser quality studs from other manufacturers. Following heat-treat, each stud is centerless ground to make it as close to perfectly concentric as possible. Next, they're thread rolled, which gives them about 1000% better fatigue strength than those studs that are threaded prior to heat-treat. You will also note that ARP® offers specially undercut studs for several engines. This procedure (done only to the shorter studs) more equalizes the "stretch" of both studs, which makes for a more consistent clamping force - and one that compensates for head gasket compression when the cylinder heads are installed. This helps prevent blown head gaskets, and assures optimum engine sealing. Premium quality chrome moly steel head stud kits are available for most every import and domestic performance compact application. You won't find a better quality stud on the market from any other source. Look for ARP® stamped on each stud as your assurance of quality. ARP Stud Kits feature: 8740 chrome moly steel alloy Precision heat-treat to 190,000 psi Centerless ground o.d.'s Rolled threads, not cut Black oxide rust-preventative finish Hex or 12-point nuts & parallel ground washers